Our Company is young, but innovative, attentive to environmental sustainability and has great productive capacity. Oleificio San Giorgio is active on the market since 2010. In the heart of the Friuli valley, Oleificio San Giorgio is an excellence in production of soybean and processes oilseeds and cereals for food, feed and industrial purposes. The plant is able to process up to 1100 Tons of soybean per day and to refine up to 180 Tons of oil.

Oleificio San Giorgio

INNOVATION, QUALITY AND PRODUCTIVITY

170.000 SQM OF PRODUCTIVE CAPACITY

The strategic location and the logistic connections offer a competitive advantage in terms of market orientation, particularly of the Eastern Europe, allowing Oleificio San Giorgio to move large quantities of goods, which may also be stored in warehouses and silos even for third account.

TECHNOLOGICAL PLANT

Established in 1997 by the entrepreneur Franco Rossetto, Oleificio San Giorgio is equipped with a highly advanced technological plant, to face the market requirements, respect the quality standards of the products and the environmental protection.

4 Silos of 2.500 cu.m./each for soybean seeds, rapeseeds and sunflowerseeds.

8 Silos of 8.500 cu.m./each for soybean seeds, rapeseeds and sunflowerseeds.

A total of 25.000 Tons of meal, divided in 4 boxes for the simultaneous storage of 4 different products

The drying area consists of two driers with the possibility to process 2 different types of seed at the same time.

Capacità di 250 t/g di essiccamento per il germe da molino con due sili polmone da 100 t cadauno.

Capacità di 1.500 t/g con tre sili polmone da 350 t cadauno per agli altri semi.

Possibilità di raddoppio degli essiccatoi per arrivare a 3.000 t/g di soia.

6 tanks of 2.000 cu.m./each for crude oil made of carbon steel with food paint.

6 tanks of 1.000 cu.m./each for refined/semi refined oil made of stainless steel Aisi 304.

4 tanks of 250 cu.m./each for refined oil for food use made of stainless steel Aisi 304

4 tanks of 50 cu.m. for oleins made of fiberglass

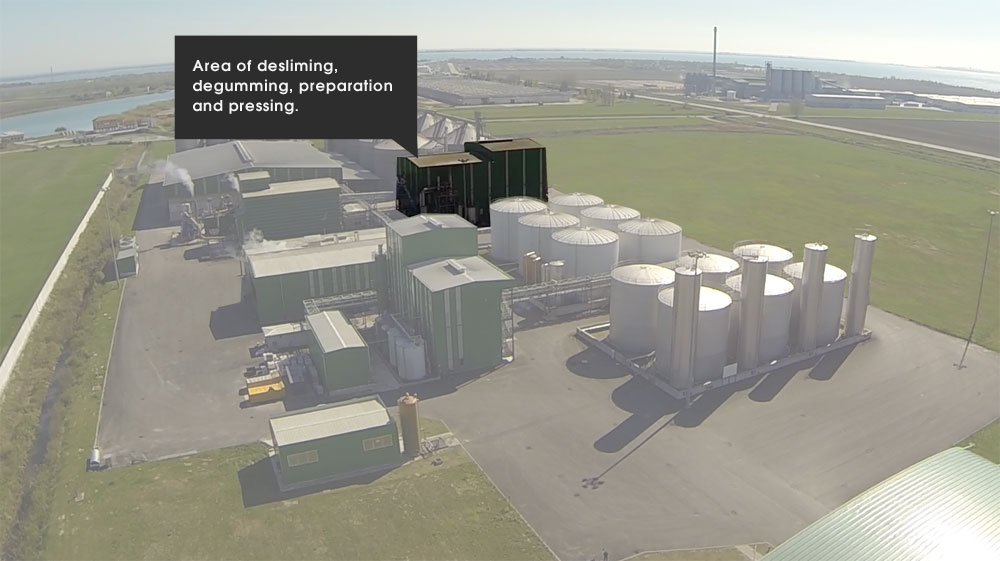

Area of desliming, degumming, preparation and pressing.

Industrial waste water is treated in a chemical-physical internal purification plant for the removal of:

- Oils and fats

- Phosphorus

- Suspended solids

Area pellettizzazione e macinazione farine

Solvent extraction area

A physical refinery plant consisting of:

- Continuous neutralization and dewaxing

- Continuous discoloration and filtration

- Continuous deodorization

- Continuous division of soapy paste

The plant processes up to 180 Tons of oil per day.

The plant processes

1.100 TONS/DAY

SOYBEAN

900 TONS/DAY

SUNFLOWERSEED

700 TONS/DAY

CORN GERM and STARCH CORN GERM

800 TONS/DAY

RAPESEED

STRATEGIC LOCATIONl

LOGISTIC CONNECTIONS BY LAND AND SEA

Our Company can count on an enviable logistics, that offers a competitive advantage in terms of market orientation.

The plant is located a few km from the highway nr. A4 and has its own railway sidings that allows to receive the raw materials directly on railway.ADVANTAGES

- Less than 10 from the highway nr. A4 Milano-Trieste

- Less than 50 km from Slovenian border and 100 from the Austrian one

- 2 km from the dock of Port Margreth

- Oleificio has a railway junction linked to the railway of the industrial area Aussa Corno, linked to the railway station of San Giorgio di Nogaro, with the possibility to receive the raw materials and to deliver the meals directly on railway.